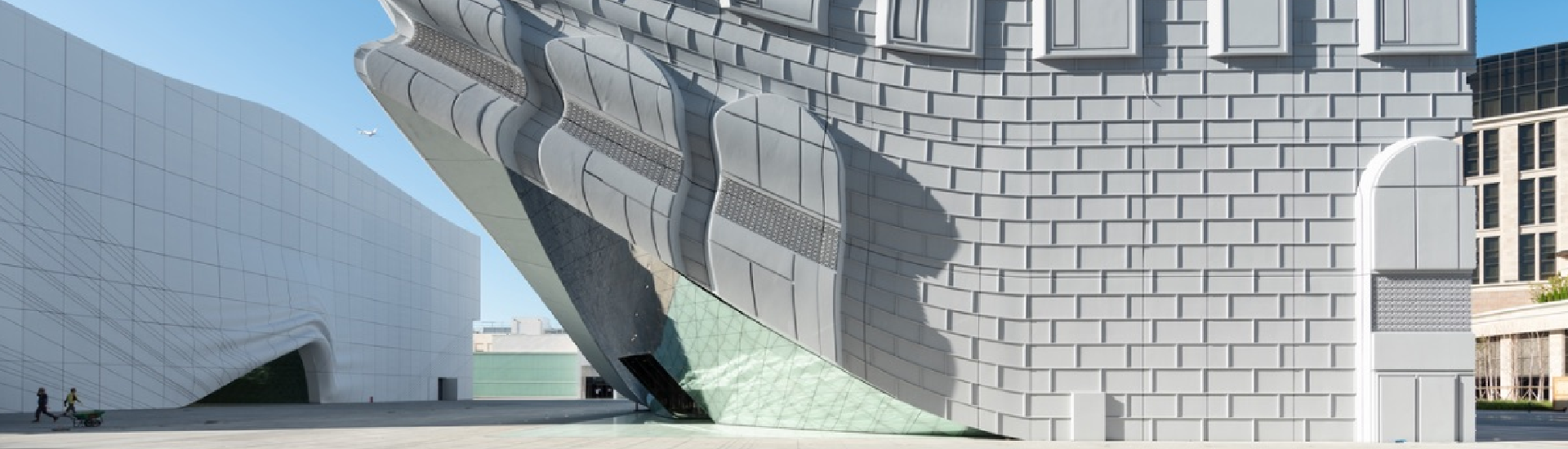

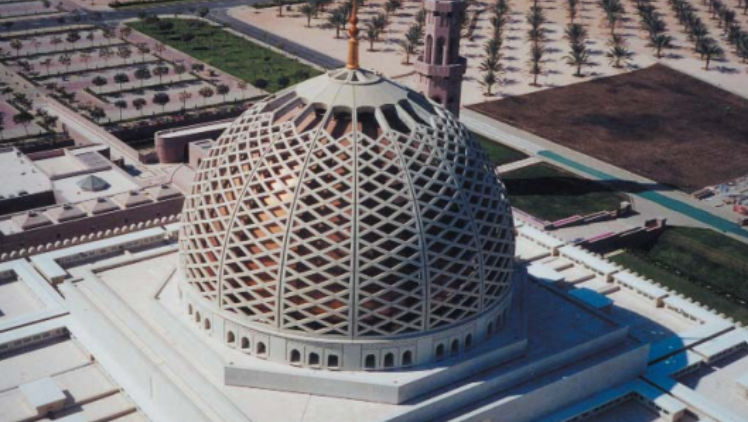

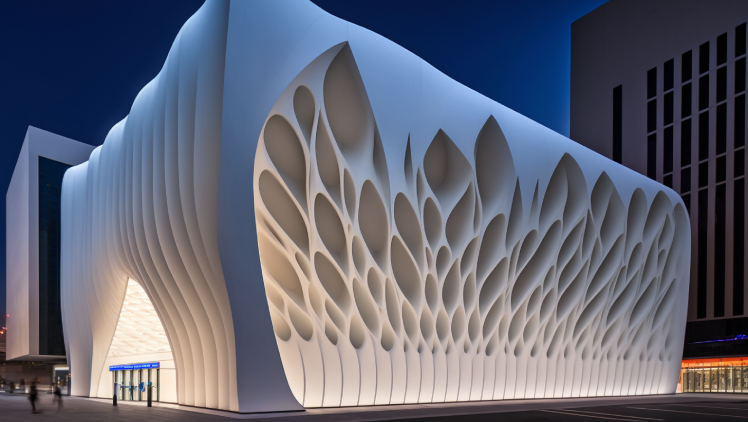

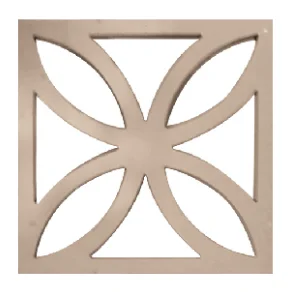

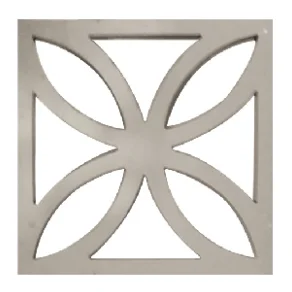

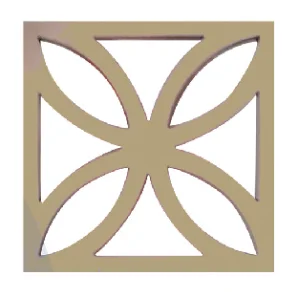

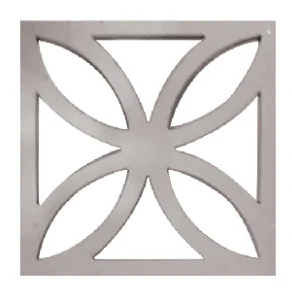

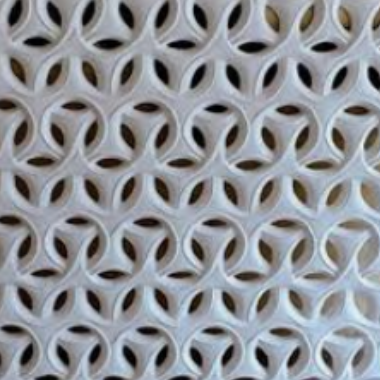

Multywin GRC Screens

Providing and fixing Glass Reinforced Concrete (G.R.C.) Screens in approved size, pattern, design, thickness and color of M/s. Multiwyn make or equivalent. The Screens should be made from '53 grade' White Portland Cement, Quartz, Fine Silica Sand, Alkali Resistant Glass Fiber manufactured by 'NEG' or equivalent, Super Plasticizers manufactured by 'BASF' or equivalent, Polymers manufactured by 'BASF' or equivalent and U.V. resistant Synthetic inorganic pigments should be used for pigmentation. The material casting should take place in Synthetic Rubber / FRP Mould.